The eight challenges

On this page you will find the challenges posted by the two companies participating in the Study Visit: UVESA and General Mills.

If you want to provide a solution for one of the challenges, click below.

About the companies

Currently the Uvesa Group is one of the leaders in the food industry in Spain thanks to its poultry, pig and feed manufacturing areas. More than 50 years dedicated to the production, processing and distribution. Vertical integration, from the egg to the final product, to provide assurance of traceability to our customers.

We are facing a digital transformation plan (I4.0) and we are interested to receive inspired solutions or ideas to solve some of our 4 internal challenges related to sensing applications.

GENERAL MILLS is a multinational manufacture of canned vegetables, Mexican food and sauces fundamentally. Old El Paso y Nature Valley are the main products.

Within General Mills San Adrian Digital transformation I4.0 plan, we are facing few challenges at technological level and we are interested to receive ideas and proposal from digital providers focused on the need described in the challenges.

Challenge 1

UVESA Challenge No.1

IDENTIFICATION OF REFERENCES

Need for the classification of the different products (parts of the chicken, thighs, breasts, …) automatically for subsequent shipment to the different lines, using Vision control and could be complemented by AI. It is intended that a Vision System identifies the reference and sends it to the packaging machine, informing the labelling or barcode of the reference so that it can be labelled with the customer’s request data and, then to send it to the packing place.

Two short videos are available for the distribution process and product identification:

General Mills Challenge No.1

DETECTION SYSTEMS

Development of alternative detection systems to X-rays and metal detectors of foreign material, metallic and non-metallic in liquids with a relative viscosity based on tomato sauces and transported in pipes.

Challenge 2

UVESA Challenge No.2

LABELLING AND BARCODE

Verification of the barcode corresponding to the product to avoid errors in the distribution to the appropriate customer, if there is an error it is rejected avoiding its return to embedded boxes.

A short video showing the process:

General Mills Challenge No.2

ONLINE LISTERIA DETECTION BIOSENSORS

Need for sensors applied to the detection and if possible, elimination of listeria in a continuous production line of snack, or cereal bars. It could be applied at various points in the process, based on the capacity of the process, when the bars are aligned or just when the bars are in the packaging process in which the speed increases considerably, 500, bars min

Challenge 3

UVESA Challenge No.3

EMBEDDED PALLETIZED

Pick up the tray, put it in the box in the specified units, palletize, identify pallet.

A short video showing the process:

General Mills Challenge No.3

BIN PICKING SEASONING AND SAUCE

The challenge consists of dosing the sauce or seasonings through a bin picking system at high cadences in a production line of Mexican food tortilla kits, the cadences will be around 80 pieces per minute, considering that they can vary in shapes and sizes, additionally, in addition a part of the camera embedded in the binpicking, a collaborative Robot will be needed that operates at high cadences with the necessary safety measures for these speeds, weight of sauce or seasoning approx 100 gr

Challenge 4

UVESA Challenge No.4

INTEGRATION OF palletizing information and product delivery note in the ERP

Using the Pallet label, identify what corresponds to the order and send the data to make the final delivery note.

General Mills Challenge No.4

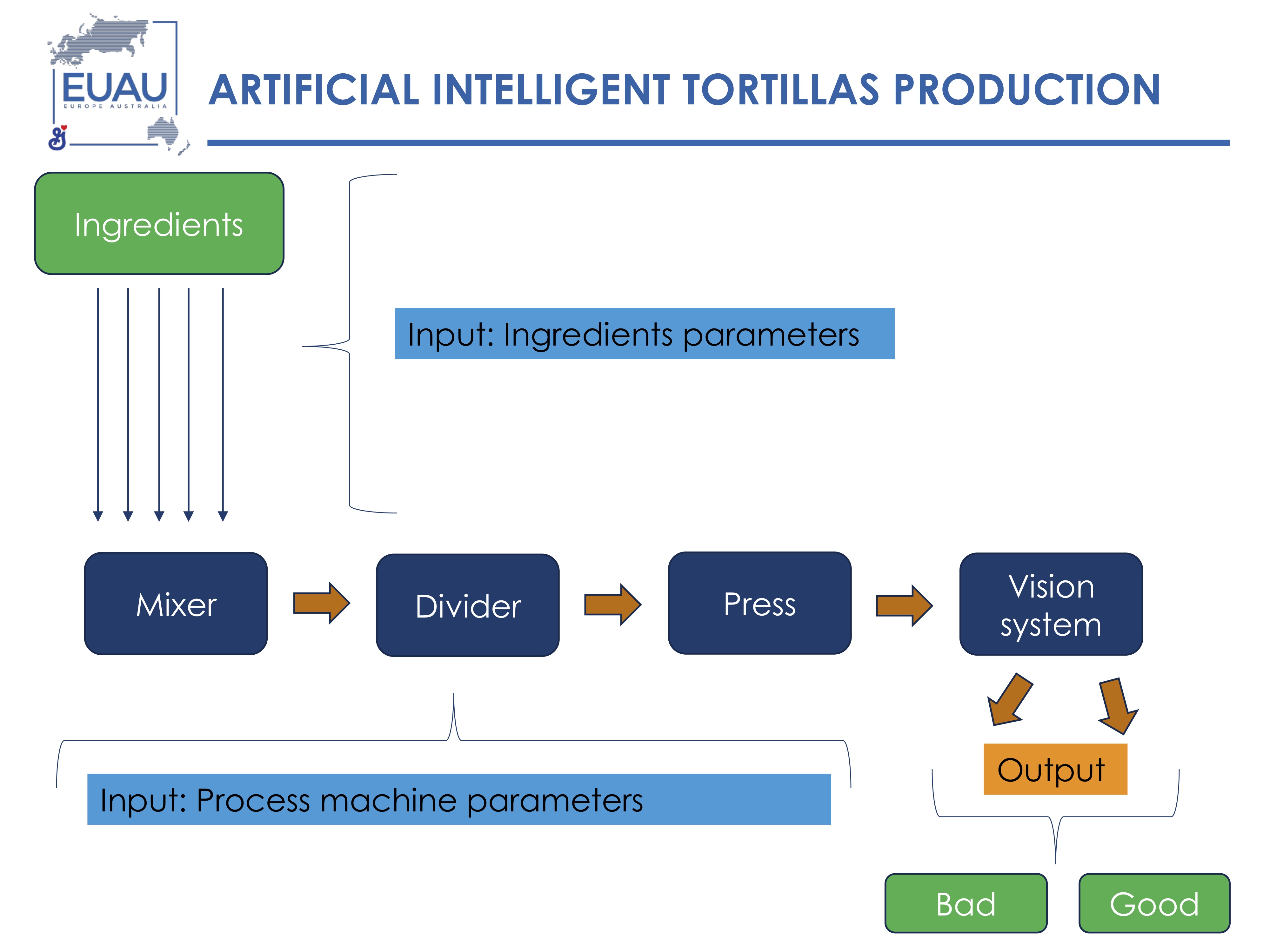

AI APPLIED TO BAKERY PROCESS, ingredients parameters process result

The tortilla production process consists of different steps that can be briefly described: ingredients (water-flour-premix), and processing (mixing – curing, pressing, baking, cooling,), then the challenge is the analysis of parameters (temperatures, humidity, characteristics, consumption motors, torque, supplier specifications, etc etc), to create an algorithm that identifies what variations in the process or what specifications are necessary for better performance and efficiency of the line

I want to provide a solutions to one of the four challenges

If you have a solutions to one of the eight company challenges described above, then click below and fill out the application form.